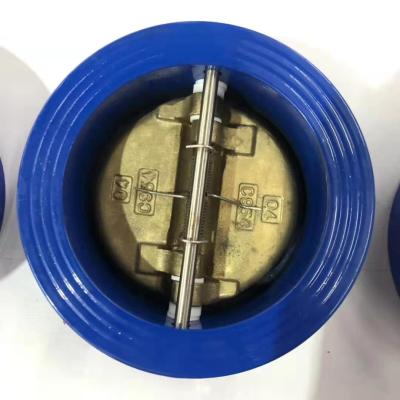

One Board Wafer Type Check Valve CF8 Disc

Check valve refers to the opening and closing parts of the circular disc and by its own weight and media pressure generated action to block the media flow back valve. Automatic valve class, also known as check valve, one-way valve, backflow valve or isolation valve. Disc motion is divided into lifting and swing. Lift check valves are similar in construction to globe valves except for the stem that drives the disc. The medium flows in from the inlet end (lower side) and flows out from the outlet end (upper side). Valve is opened when inlet pressure is greater than the sum of disc weight and flow resistance. On the contrary, the valve is closed when the medium flows back. Swing check valves have a disc that is tilted and rotates on its axis and work in a similar way to lift check valves. Check valves are often used as bottom valves in pumping units to prevent the backflow of water. Check valves are combined with globe valves to provide safety isolation. Disadvantages are large resistance, poor sealing when closing.

At the contrary, the valve is closed while the medium flows back. swing test valves have a disc this is tilted and rotates on its axis and paintings in a similar way to lift test valves. check valves are often used as bottom valves in pumping units to save you the backflow of water. check valves are combined with globe valves to provide safety isolation. risks are large resistance, poor sealing when final.

Cast Iron Wafer Type Check Valve

Material:

The body materia: GG25,GGG40,GGG50

The disc material: DI/SS304/SS316/AL-BZ

The stem/spring material: SS416/SS304

The seat material:NBR/EPDM/VITON

Standard:

ANSI/JIS/DIN/BS

Usage:

They are used for pipe of transporting water with such medium as water sewage and seawater.It can avoid media flowing backwards and prevent damaging water hammer,guarantee the safety using of pipes.

Features:

1. The products are new structure .small and light weight

2. Reliable sealed,endurable open-close,erar-resisting,long life.

3. With less flowing resistance than old check valve and obvious enerfy-saving effects.

Technical Parameters:

| Seal | 18Bar | 11Bar |

| Operating Temperature | -10℃~+120℃ | |

| Operating Environment | Ballast and bilge system Chemical processing | |

| Desalination plants Drilling rigs | ||

| Drinking waterDry powder | ||

| Food and beverage Gas plants | ||

| HAVC Mining industry | ||

| Paper industry Sand handling | ||

| Seawater | ||

| Sugar industry | ||

| Thermo technical water treatment | ||

| Waste water | ||

Related News

Submitted successfully

We will contact you as soon as possible