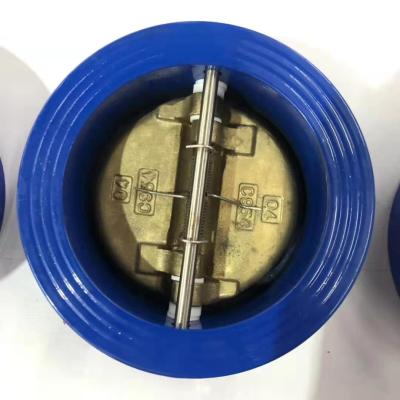

Dual Disc Spring Loaded Wafer Check Valve

1. Zero fugitive emission design

2. Versatile functionality for horizontal and vertical installations.

3. Low weight design / 80% - 90% weight reduction compared to full body swing check valves.

4. Simplifies piping, optimizes space utilization, and lowers installation costs.

5. Low cracking pressure and overall pressure loss

6. Alleviates water hammer and resulting damaging effects

Test valves are often used as bottom valves in pumping gadgets to prevent the backflow of water. take a look at valves are blended with globe valves to offer protection isolation. dangers are huge resistance, terrible sealing when last.

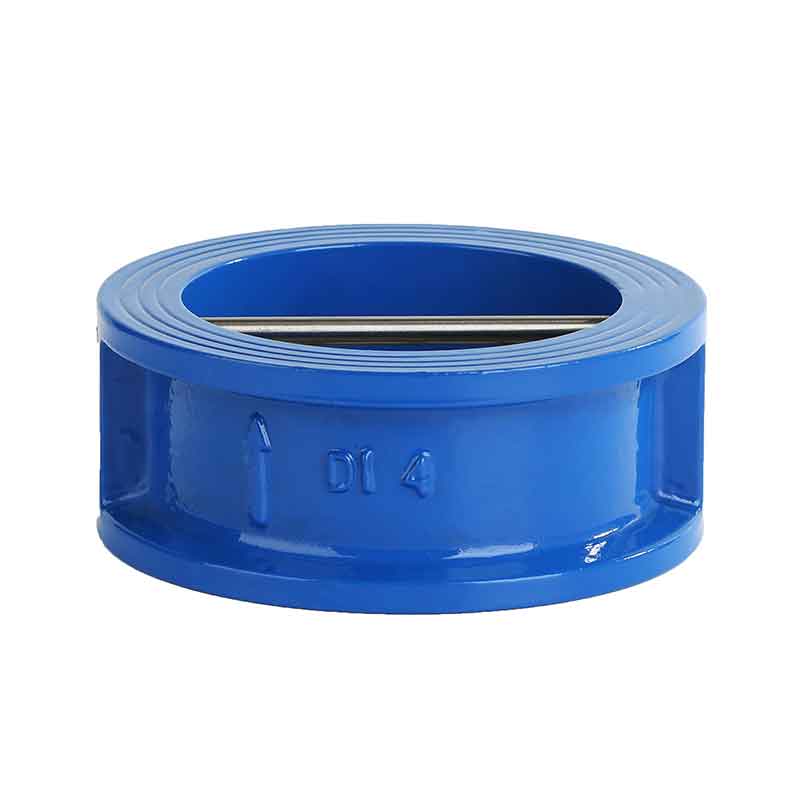

Cast Iron Wafer Type Check Valve

Material:

The body materia: GG25,GGG40,GGG50

The disc material: DI/SS304/SS316/AL-BZ

The stem/spring material: SS416/SS304

The seat material:NBR/EPDM/VITON

Standard:

ANSI/JIS/DIN/BS

Usage:

They are used for pipe of transporting water with such medium as water sewage and seawater.It can avoid media flowing backwards and prevent damaging water hammer,guarantee the safety using of pipes.

Features:

1. The products are new structure .small and light weight

2. Reliable sealed,endurable open-close,erar-resisting,long life.

3. With less flowing resistance than old check valve and obvious enerfy-saving effects.

Technical Parameters:

| Seal | 18Bar | 11Bar |

| Operating Temperature | -10℃~+120℃ | |

| Operating Environment | Ballast and bilge system Chemical processing | |

| Desalination plants Drilling rigs | ||

| Drinking waterDry powder | ||

| Food and beverage Gas plants | ||

| HAVC Mining industry | ||

| Paper industry Sand handling | ||

| Seawater | ||

| Sugar industry | ||

| Thermo technical water treatment | ||

| Waste water | ||

Related News

Submitted successfully

We will contact you as soon as possible