Pneumatic Butterfly Valve Staliness Steel

1, small and light, easy disassembly and maintenance, and can be installed in any position.

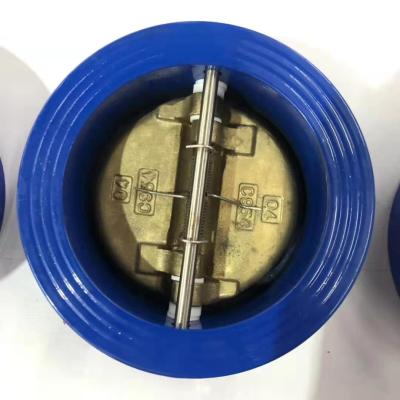

2, simple structure, compact, small operating torque, 90° turn to open quickly.

3, the flow characteristics of straight line, good regulation performance.

4. The connection between butterfly plate and valve stem adopts no pin structure to overcome the possible internal leakage point.

5, butterfly plate outer circle using spherical shape, improve the sealing performance and prolong the service life of the valve, with pressure open and close more than 50,000 times still maintain zero leakage.

6, the sealing parts can be replaced, and the sealing is reliable to achieve two-way sealing.

7, butterfly plate can be spraying coating according to user requirements, such as nylon or ptfe.

8, the valve can be designed as flange connection and clamping connection.

9, the driving mode can choose manual, electric or pneumatic.

Size:

DN25-DN1200

Material:

Body:Cast Iron/Ductile Iron/Cast Steel

Disc:DI+Ni/SS304/SS316/AL-BZ/CF3M/SS2205/SS2507

Stem:SS416/SS304/SS316/17-PH/Monel K500

Seat:EPDM/NBR/VITON/PTFE/HYPALON

Operation:Handlever /Gearbox/Electric / Pneumatic

Standard:

Design Standard:EN 593 , MSS SP67 API 609 BS5155

Inspection & Test:API 598 ISO 5208 EN 12266

End Standard:ANSI B16.1 CL. 125LB /B16.5 CL. 150LB /AS 2129 Table D & E / DIN 2501 PN6, PN10 & PN16

/EN 1092 PN6, PN10 & PN16/ISO 2531 PN6, PN10 & PN16/ISO 7005 PN6, PN10 & PN16 / JIS B 2210 5K & 10K

Face to Face:ISO 5752 , EN 558 , MSS SP67 and API 609 DIN3202

Top Flange:ISO 5211

Related News

Submitted successfully

We will contact you as soon as possible