The principle of check valve opening and closing

The check valve opening and closing parts are opened or closed by themselves by the flow and force of the medium to prevent the backflow of the medium. The valve is called a check valve. The check valve belongs to the automatic valve category, which is mainly used in the pipeline where the medium flows in one direction, and only allows the medium to flow in one direction to prevent accidents. The check valve, also known as a one-way valve or a check valve, is used to prevent the backflow of the medium in the pipeline. The bottom valve of the water pump suction valve also belongs to the check valve category.

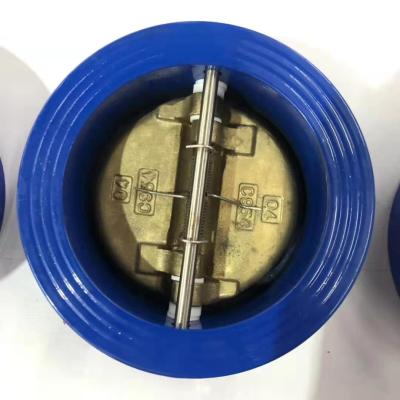

According to the structure, check valves can be divided into three types: lift check valves, swing check valves and butterfly check valves. Lift check valve can be divided into vertical and horizontal. The swing check valve is divided into three types: single-lobe, double-lobe and multi-lobe. The butterfly check valve is a straight-through type. The above types of check valves can be divided into three types: threaded connection, flange connection and welding.

The installation of the check valve should pay attention to the following things: 1. Do not make the check valve bear weight in the pipeline, and the large check valve should be supported independently so that it will not be affected by the pressure generated by the piping system. 2. During installation, pay attention to the direction of medium flow should be consistent with the direction of the arrow on the valve body. 3. The lift-type vertical flap check valve should be installed on the vertical pipeline. 4. The lift-type horizontal flap check valve should be installed on the horizontal pipeline