Advantages and Disadvantages of Butterfly Valve

Advantage

1. The opening and closing is convenient, quick, labor-saving, low in fluid resistance, and can be operated frequently.

2. Simple structure, small overall size, short structural length, small volume and light weight, which is suitable for large-diameter valves.

3. Mud can be transported, and the liquid accumulated at the pipe mouth is the least.

4. Under low pressure, good sealing can be achieved.

5. Good adjustment performance.

6. When fully opened, the effective circulation area of the valve seat channel is large, and the fluid resistance is small.

7. The opening and closing torque is small, because the butterfly plates on both sides of the rotating shaft are basically equal to each other under the action of the medium, and the directions of the generated torque are opposite, so the opening and closing is labor-saving.

8. The sealing surface material is generally rubber and plastic, so the low-pressure sealing performance is good.

9. Easy installation.

Disadvantage

1. The range of operating pressure and working temperature is small.

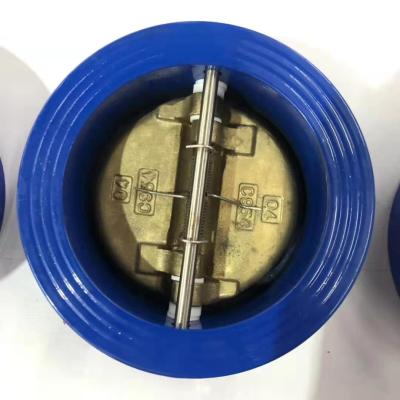

2. Poor tightness.Butterfly valves can be divided into offset plate type, vertical plate type, inclined plate type and lever type according to their structural forms.

According to the sealing form, there are two types: soft sealing type and hard sealing type. Soft seal type is usually sealed by rubber ring, and hard seal type is usually sealed by metal ring.

According to the connection type, it can be divided into flange connection and clamp connection; According to the transmission mode, it can be divided into manual, gear transmission, pneumatic, hydraulic and electric.

The operation is flexible and labor-saving, and manual, electric, pneumatic and hydraulic modes can be selected.